Product Summary

Are you adding new products to your list? Is your competition getting tougher? Do you need to gain efficiency and speed in your operations? Would you like to get things done better, faster and more economical?

The challenges of new century inventory logistics can only be addressed with fresh new solutions. Overcome these challenges using PRISM to easily add intelligence to your supply chain management.

PRISM, the Prediction Inventory System Manager is a powerful software that can easily handle a broad spectrum of difficult tasks including sales forecasting, inventory management and data collection, production scheduling, packaging and raw materials scheduling, driver transport and product distribution. PRISM’s modular design allows any company to snap in any module to improve their existing software system. Because the modules are integrated, the whole supply chain can be managed with the full suite of tools. With PRISM, you can now control your entire distribution network from a birds-eye view. PRISM is very easy to learn to use because it is designed to work using the latest Microsoft Windows operating system.

Learn More

Accurate Sales Forecasts are Intelligently and Automatically Generated in Minutes

PRISM Sales Forecasting System will increase your forecasting accuracy, reduce error and add consistency.

If you know to a high degree of certainty what you will sell in the future, then your business is in a better position to produce, store and ship its products efficiently. In fact, without an accurate sales forecast, you cannot even begin to make good decisions about operations planning. PRISM combines your sales and marketing goals with actual sales data from the past to accurately develop a future demand plan.

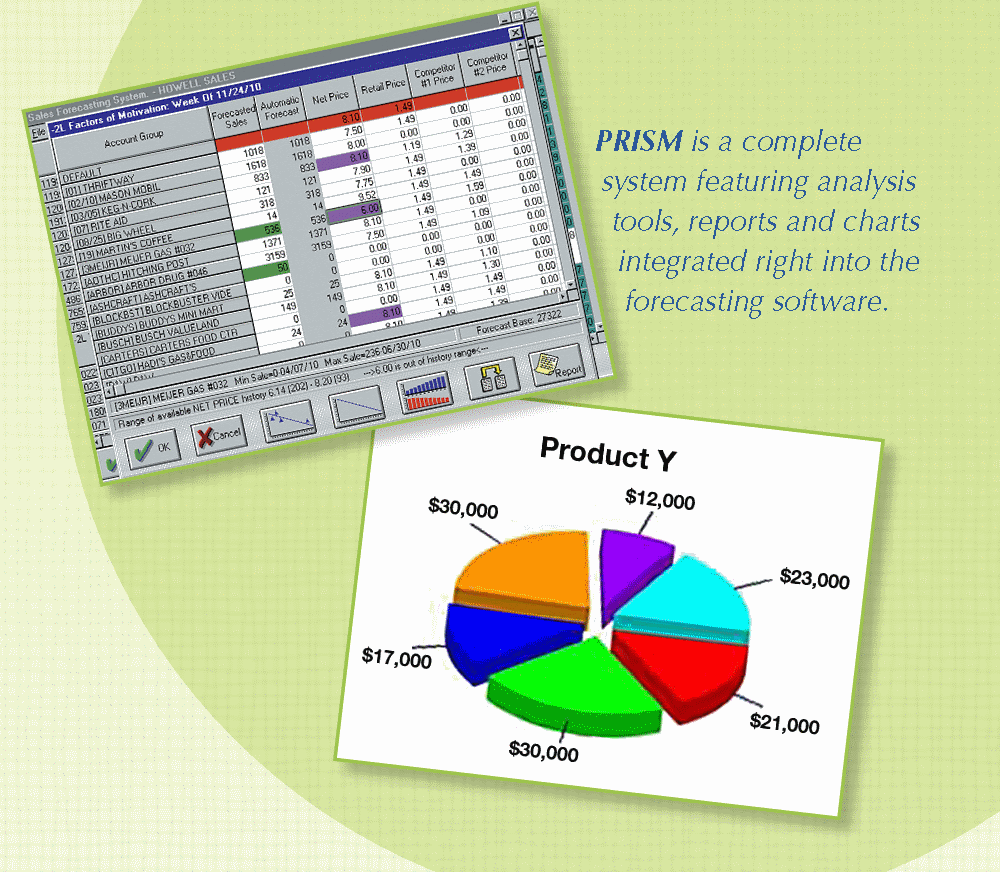

Speed and intelligence are at the core of the PRISM forecasting methods. High accuracy is obtained by combining well known and proven statistical formulas with plain old fashioned common sense. With multiple levels of detail you can develop forecasted sales by day or by week and aggregate into months, quarters and years. Plus you can roll up or drill down all the way from the enterprise, to a single sales center, package grouping, individual product code, account group and customer levels. Statistical methods available include exponential smoothing, gauss-jordan polynomial curve fitting, year by year growth indexing, and carefully developed proprietary methods. You can consider all your own motivational factors such as seasons and holidays, introduction of new products, retail and net pricing, competition pricing, historical sales and other factors you can define, track and correlate.

Learn MorePRISM Advantages

Quickly achieve the following measurable benefits by implementing PRISM Sales Forecasting System now:

Reduce waste and increase profit

Save time of planning personnel and sales account managers

Utilize your production lines and transport trucks more fully

Cut operational costs and eliminate double handling of product

Have a fresher better-tasting product through lower inventory and better rotation

Cut down your occurrence of out-of-stocks and increase product availability

React faster by anticipating different patterns of sales

Reduce error and increase accuracy

Relate sales volume to price or other factors, statistically

Improve customer service and loyalty

Generate continuous replenishment process inputs (CRP)

Analyze and suggest planned replenishment orders (SRO)

Following the automatic generation of sales forecasts, you still remain in complete control to manually adjust the results and put your special finishing touches on any forecast at any level. Converting and importing sales and other data from internal, legacy and third-party systems is a snap. Use the PRISM import utility to bring in data in different forms.

PRISM is a complete system featuring analysis tools, reports and charts integrated right into the forecasting software. You can’t improve what you don’t measure so that’s why you can quantify, review and manage forecast error and accuracy with numerous performance measurement reports.

Increase your company’s forecasting discipline today. Implement PRISM Sales Forecasting System software.

PRISMpad Mobile Inventory Data Collection in the Palm of your Hand

Quickly count actual inventory or record transactional data using mobile hand held computers with scanners.

Speed up your process and reduce errors, while collecting batch codes, lot numbers, date codes and warehouse locations.

Deciding what to promise a customer, what to ship on a truck, or how much to produce are choices that rely on an accurate understanding of your true and real inventory levels. do you currently have a full understanding of all you actual warehouse inventory levels so that you can plan your operation and serve your customers better? This information is critical to scheduling, planning and executing your daily business activities. Quickly gathering, verifying and sharing transactional and inventory data is necessary to serve your customers better. PRISMpad is the software your company needs to handle this and more.

PRISMpad is software that uses a variety of pen-based hand-held computers that are light, small and provide bar code scanning capabilities. This tool can count and categorize finished goods, raw materials, packaging, supplies and ingredient materials. Inventory can be gathered and classified many ways, such as on quality control hold, on a truck, or warehouse floor. With one complete software tool you can gather freshness date codes, lot numbers, batch codes and warehouse aisle and row information. Count and reconcile your inventory earlier in the day, without error, then export the data to other inventory systems such as financial tools or legacy inventory management systems.

Learn More

Achieve the following major benefits and improvements by using PRISMpad software:

Eliminate your current paper-based process of collecting inventory data; Go paperless

Use bar code scanners to capture product information from custom bar code labels or UPC codes

Gather the freshness date code, lot number, batch ID, or warehouse aisle and row location

Gather the production lot number tracking code, batch codes or other codes

Export and import data from your legacy or third-party inventory or financial systems

Let the computer do the math and eliminate errors

Paperless process gets rid of all keypunch mistakes, and eliminates re-keying of data

Finish your inventory earlier in the day and distribute and use the valuable information sooner

The system is easy to implement, easy to train and learn, and has a very fast return on investment

Works on a wide spectrum of hand-held computers supporting Windows Mobile or PocketPC

Following the automatic generation of sales forecasts, you still remain in complete control to manually adjust the results and put your special finishing touches on any forecast at any level. Converting and importing sales and other data from internal, legacy and third-party systems is a snap. Use the PRISM import utility to bring in data in different forms.

PRISM is a complete system featuring analysis tools, reports and charts integrated right into the forecasting software. You can’t improve what you don’t measure so that’s why you can quantify, review and manage forecast error and accuracy with numerous performance measurement reports.

Increase your company’s forecasting discipline today. Implement PRISM Sales Forecasting System software.

With the PRISM desktop inventory software, you can also study your inventory data to gain insights never before seen. Charts and reports can identify relationships between many management indicators such as days-of-supply, floor space utilization, inventory level over time and out-of-stocks. now you can study the big picture. Plus with the freshness and product quality reporting tools you can implement an age status classification system to proactively identify out-of-date issues before they occur. easily locate the position of individual pallets in your building.

Prediction Software Incorporated is a value-added reseller of mobile computers. Some brands we recommend include Intermec norand®, Motorola, Fujitsu and Hand-held products from Honeywell.

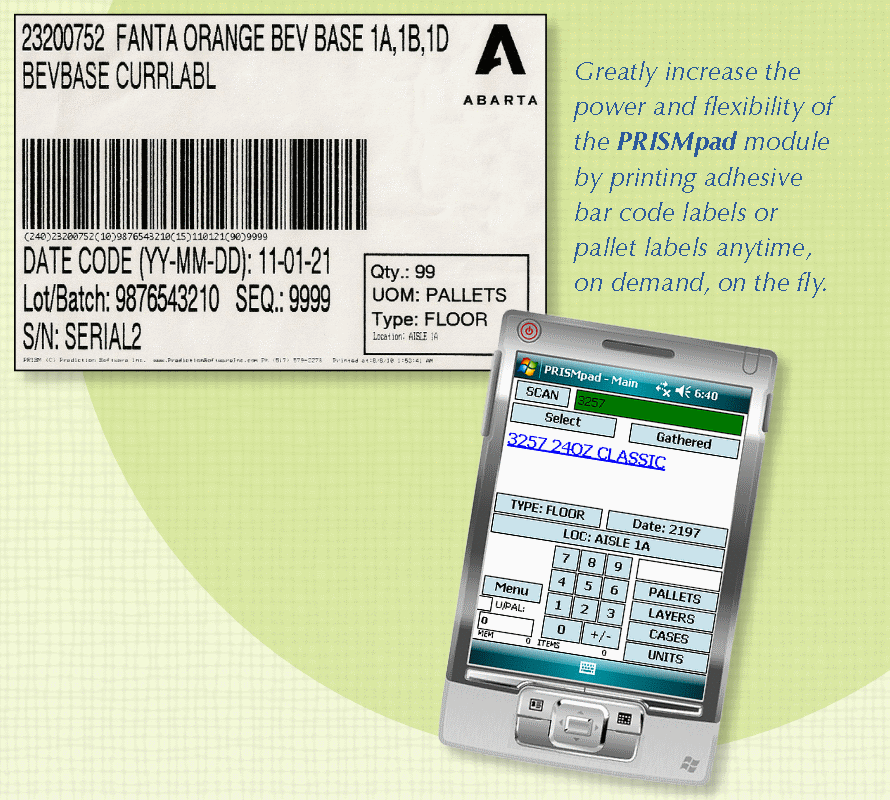

PRISMpad Mobile Printing of Product Bar code Labels

Flawlessly produce professional bar code labels using small wireless mobile printers attached to your belt.

Counting inventory, receiving shipments, or recording any inventory transaction is a lot easier, faster, and more accurate when you can scan the bar code on the products. But what if the bar code label is missing, incomplete, damaged, hard to reach, doesn’t conform to your company’s codes or standards, or doesn’t contain any human readable text on the label? now with the power of PRISMpad you can print a new or supplemental adhesive bar code label, in multiple sizes, containing all relevant product information including human readable product description text and your company logo.

Learn MoreFlawlessly produce professional standards-based bar code labels using small ruggedized wireless mobile printers attached to your belt. Transmit printed label data from your hand held computer wirelessly to the printer using bluetooth, wireless ethernet, or USB connections. Both direct thermal and thermal transfer adhesive bar code labels can be printed in widths of 2”, 3” or 4” and any length needed. Labels on receipt journal paper without adhesive or backing can also be produced easily.

The versatility of on-demand label generation allows your company the flexibility to print just one or two very small labels as needed for tiny packages, bottles or boxes. It’s also easy to generate hundreds of full size serialized pallet labels containing material number/SKU, product description, package description, date code, lot or batch number, sequence number, serial number, and optionally: quantity, unit of measure, transaction type, and location address in the warehouse.

Some suppliers of concentrate, raw materials and ingredients have removed the human readable information from their labels altogether, providing a label with only a bar code and no text. When these items are received and checked in, PRISMpad can easily scan, decode and display the various fields of information in the manufacturer’s labels, allowing the ability to print a new human readable adhesive label. With the new label, when the concentrate, raw materials and ingredients are put away, anyone can identify the contents without needing a scanner.

Many third-party suppliers of finished goods ship their products without any bar coding at all. now, affixing a proper bar code label to these products is no problem. When the time comes to count inventory, scan your new bar code on these items quickly, easily and accurately. Addi-tional features include the ability to scan and automatically cross-reference external supplier product codes, printing a new label showing your company’s own logo, internal standard product code and a new bar code.

PRISMpad prints and reads worldwide industry standard GS1-128 bar code symbols, enabling several pieces of information to be packed into a single bar code. This means a single scan can yield information about many details including the product code, lot or batch number, date code, sequence number, and other relevant information. Any supply chain partner can also scan and understand the multiple fields of information encoded in these labels. every time inventory is counted, all date code information is automatically collected because it’s inside the same bar code. Having complete date code information every time inventory is counted enables freshness and product rotation reporting to be available at all times. Age status classification and financial risk management due to out-of-date product, just got a lot easier.

PRISMpad Mobile Batch Verification System

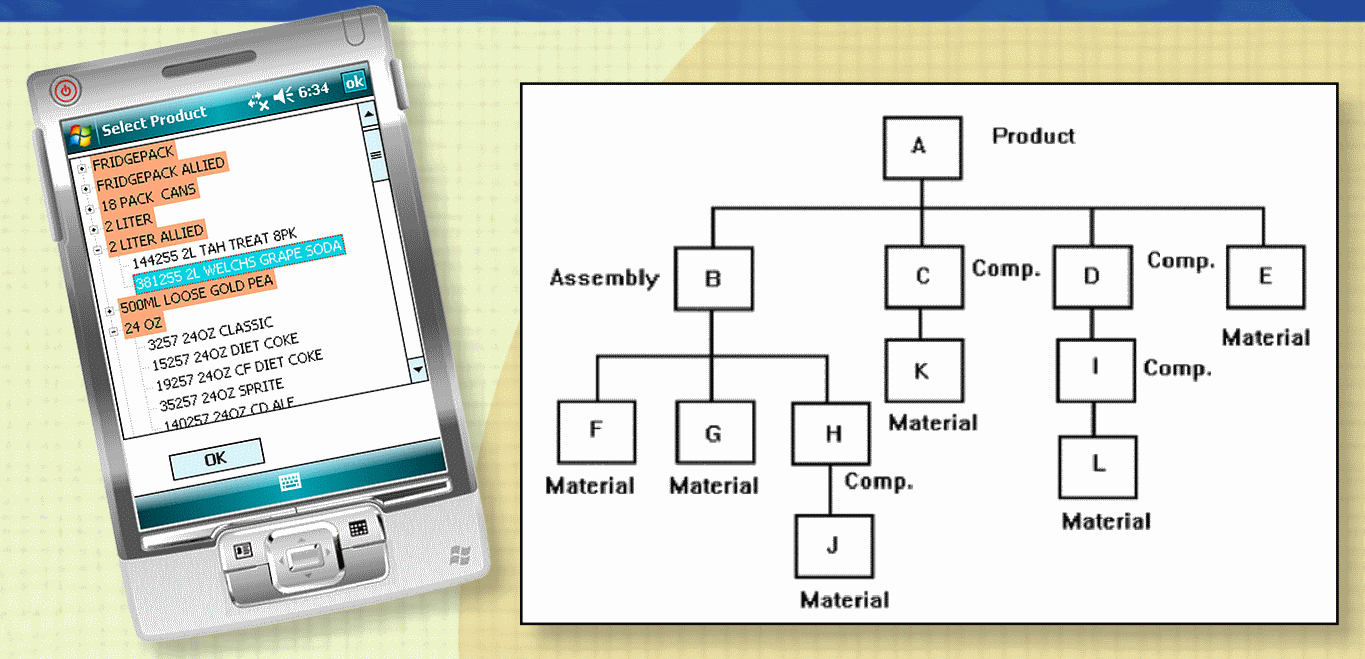

Support and improve the production batching process. Significantly reduce blending errors, provide consistency, Bill of Material standardization, auditing, batch and component traceability.

Mistakes in preparing and blending syrup batches can be very costly. If the wrong ingredients are used, or not used in the correct quantity, or if out-of-date ingredients are used, the results can be devastating; Your company can suffer the complete loss of very expensive concentrate ingredients and raw materials and possibly have to pay extra to dispose of the wasted batch. Additionally, if the mistake is not caught in time before the product is packaged and distributed, the manufacturer can also lose the cost of the packaging, and possibly have to bear the cost of a very expensive public product recall, not to mention the possible impact on customer perception of the product and brand reputation.

Learn More

PRISMpad can help ensure that doesn’t happen by providing a paperless tool to capture inventory data during the concentrate and raw material receiving process, and assist syrup and product batching with support for mobile picking, staging and verification of needed ingredients, based upon your standard bill of material recipes, and provide complete component traceability to comply with FdA requirements.

When raw materials or ingredients are received from each supplier, use PRISMpad to scan and verify the shipment against the order. If bar code data is missing or incomplete, it allows the entry of the quantity, unit of measure, date code, put-away location, batch or lot code, sequence number, supplier and bill of lading number, and ability to print a new adhesive label. The software assists in the warehouse storage process by suggesting standard “put-away locations” as defined in the product master database. Record actual put-away locations or notes about each item received. enable the transfer of this inventory transaction data to the shipping/receiving module in PRISM where it can update the online inventory and view or print various reports including unmatched shipping and receiving reports.

Interfacing directly with your production schedule, PRISMpad allows the selection of a finished product or syrup flavor and the confirmation or entry of a quantity to produce. It displays the associated standard bill of material recipe (BOM) and “explodes” required components for the production or syrup batch, including concentrate, ingredients, raw materials and packaging materials. FIFO based pick lists can be generated. Pen based wireless scanning computers allow operators to scan and record product codes, date codes, batch/lot numbers and other component and tank details about the batching process, reducing manual entry and giving real time feedback about concentrate scans.

The system requires batching personnel to scan or input information including the quantity and product being pro-duced, the tank number, amount of water, the configuration, total amount, date code and batch/lot code of each staged concentrate item, ingredient or raw material. The system compels batch operators to stage the exact needed quantity of each ingredient, find missing components based upon oldest date code, and alerts operators when aged components have exceeded the expiration date. Audible feedback also alerts operators to issues. Standard “put-away” locations are provided to make locating ingredients in the warehouse easier. When all the batch requirements are met, PRISMpadgenerates a hard copy batch “verification ticket” printout or code showing all the details of the batch and confirming the batch is properly staged according to the Bill of Material recipe. The verification ticket or code is only generated when all requirements are met, acting as a printed validation to continue with blending. This capability catches blending errors before they occur, providing another important layer of protection against potential mistakes while ensuring batching accuracy.

PRISMpad also improves traceability by recording the lot numbers and batch staging data associating every finished goods production run with the components used to make that product. This data updates the inventory system and subtracts from the available concentrate and ingredient inventory. easily look up batch verification tickets based upon the date, product code, or batch/lot numbers of finished goods or concentrate and ingredients. details of the batch verification ticket can be easily found for a particular finished good production run, or generate a list of all the production runs which used a particular concentrate or raw material batch/lot code. Providing full traceably has never been easier.

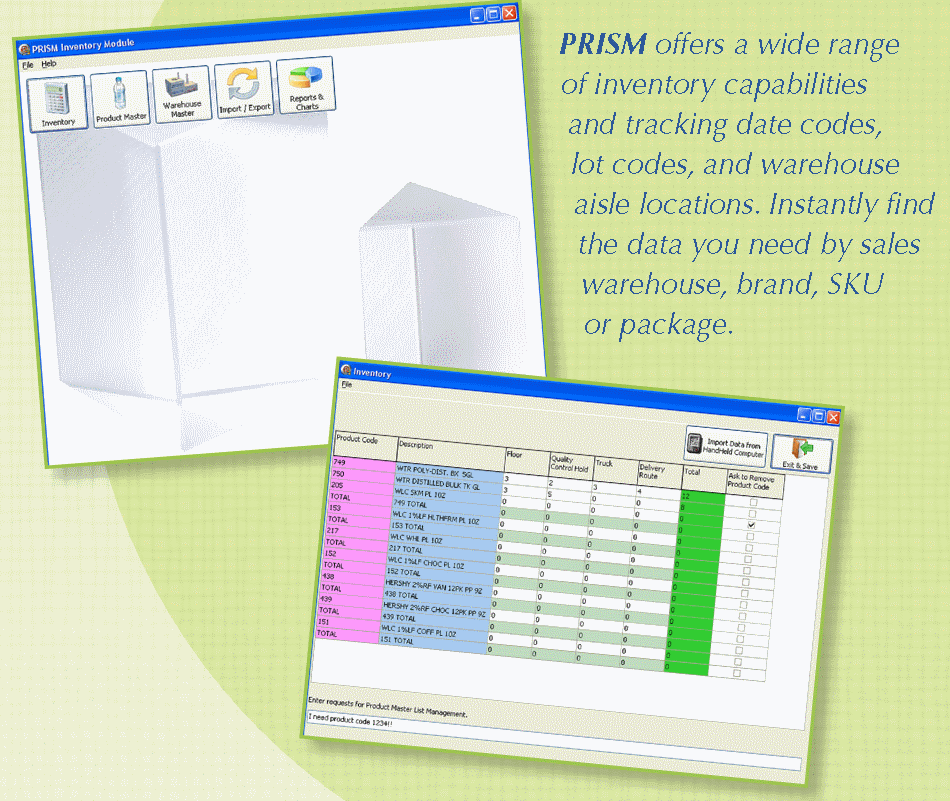

PRISM Perpetual Inventory Management System

Reduce unexplained inventory loss while managing several sales warehouses from a birds-eye view.

Accounting for all the activities in your inventory warehouse is so much easier when you have the right software designed specifically for your type of business. Regardless of the size of your company, PRISM Perpetual Inventory Management System will add consistency and standardization to your inventory process. With the ability to gather physical inventory for every product, or to cycle-count only those items with activity, PRISM will efficiently manage your reconciliation process. You can configure PRISM to track and report on many standard transaction types, such as sales, production, shipment transfers in or out, exchanges, warehouse or production breakage, quality assurance sampling, donations or custom transaction types you define. Full analysis tools let you customize charts, graphs and reports to monitor and control inventory overages and shortages, reduce shrinkage and reduce unexplained inventory loss. By comparing your theoretical inventory against actual you can see the daily and period-to-date overage and shortage. You can then find and correct inventory problems. All these tools work for finished goods as well as raw materials, packaging, ingredients and supplies.

Learn MoreAchieve the following major benefits and improvements by using PRISM Perpetual Inventory Management System:

Use equivalence to convert inventory units into dollar terms such as standard floor cost or other financial measures; get a daily valuation of your inventory

Increase utilization of your existing warehouse storage space

Connect directly to hand-held mobile computers to download inventory counts and transactions

From a birds-eye view, see your entire inventory across multiple warehouses and plants in your larger enterprise

Accumulate valuable historical data, useful for analysis and study

Easily spot trends of breakage and unexplained inventory loss; Stop wasteful activity

View or print valuable table-formatted reports and customizable graphical charts

Correlations in the historical data can now be revealed

Maintain adequate stock levels in terms of days-of-supply and help reduce required inventory

PRISM gives you access to a wealth of management information about your entire business. easily answer questions and make decisions regarding inventory, out-of-stocks, days-of-supply, guideline minimum and maximum inventory levels, warehouse space usage, or other transactional data such as production, purchases and shipments. With automatic inventory estimation capability you can view your theoretical inventory based upon transactional data, even when fresh physical inventory counts are not collected. Using your scheduling plans for purchases, production and transfers you can even estimate your future inventory and proactively manage issues before they occur.

PRISM also provides tools to help you decide and suggest how to most effectively use the existing warehouse space in your system. By defining your total available warehouse storage space, and configuring your product priorities, and sales demand data, PRISM can help you decide how to allocate floor space. With an intelligently designed plan for your warehouse space, you will be able to avoid out-of-stocks, reduce inventory costs, and reduce inventory levels while ensuring product availability.

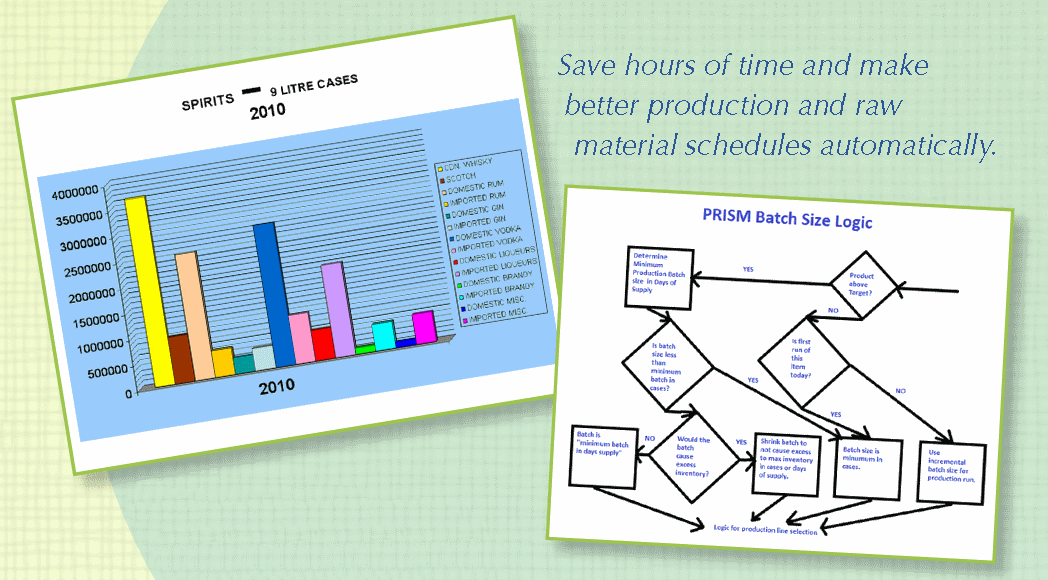

PRISM Production Scheduling and Raw Materials Ordering

You control the logic, policies and limitations guiding the automatic suggestion of your schedules.

Powerful decision support tools give you everything needed to make the best possible production schedules, automate everything using your standards and policies, and to generate timely procurement orders for raw materials, packaging, ingredients and supplies.

Separate but highly integrated modules combine to offer you a sophisticated manufacturing scheduling and planning system. Systematize your materials resource planning (MRP) with the dynamic capabilities and advanced features of PRISM.

Does your manufacturing schedule constantly change due to a myriad of ever shifting inputs such as sales forecast adjustments? With PRISM you can automate much of the decision-making by defining your policies, capacities, rules and other parameters and then let the computer rapidly and automatically generate or re-generate suggested schedules. You can now react quicker and provide powerful schedul-ing software that anyone in your organization can use.

Learn More

With PRISM you can define your production line details, cases or units per hour, change-over rules and limits, incremental and minimum batch sizes, sanitation require-ments and many other standards and conventions used by your manufacturing plants. With everything defined and organized PRISM can then rapidly generate suggested production schedules or multiple versions of the schedule for your consideration. To make a new schedule, simply change any input such as the inventory, sales forecast or batch rules, then press a button to get a new suggested schedule in a matter of seconds.

Achieve the following major benefits and improvements by using PRISM Production Scheduling and Raw Materials Ordering software:

Save hours of wasted time by your scheduler/planner revising schedules; let the computer do all the work

Systematically observe and work with manufacturing capacity, space and time limitation

Cut manufacturing costs and increase material and ingredient yield

Ensures continuous product availability and keeps your product flowing in the supply chain

Generate automatic and detailed production schedules, by plant, line, day and by shift

Use your manpower, warehouse storage space and production lines to their fullest benefit

Work with real-world limitations and preferences

Double check the viability of scheduled orders automatically using the system; see system generated “red-flags” if something is wrong

Confirm on a truckload-by-truckload basis orders received versus original orders

Helps your quality control laboratory and batch mixing control room

PRISM Raw Materials Ordering software lets you quickly create procurement schedules to support the in-flow of items needed in your manufacturing process. Support is provided to define on a material by material basis whether to use just-in-time (JIT) or minimum/reorder point methods. Virtually any product can be defined in the Bill-of-Material (BOM) and used to supportordering for concentrate, wraps, containers, lids, cans, bottles, preservatives, sweeteners, gases or other materials. You remain in total control and can add your finishing touches or revisions to any schedule or even manually generate parts of the schedule that require special handling.

PRISM supports transmitting your orders to suppliers in many ways, from simple faxing, email, data transmission using triggered exports and electronic data interchange (EDI). Best of all, when your production schedules change and require adjustment to the corresponding raw material orders, PRISM can make new schedules automatically in a matter of seconds. never shut down your production lines again due to running out of raw materials or packaging materials.

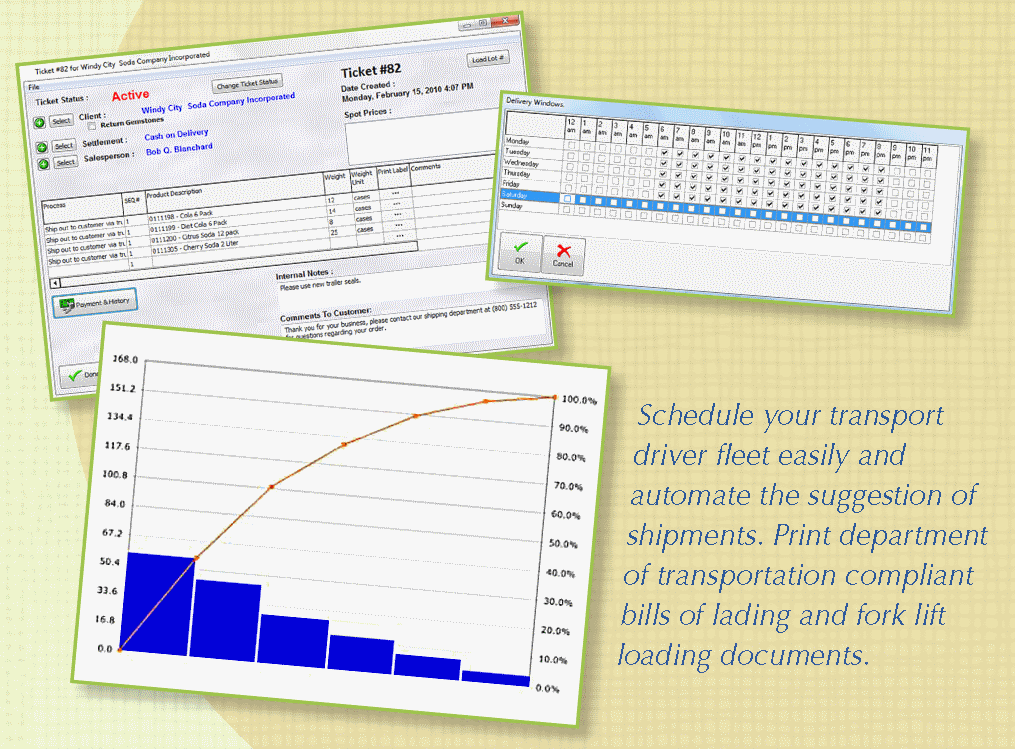

PRISM Driver Transport Scheduling & Distribution Planning System

Automatically generate suggested driver transport schedules, bills of lading and forklift loading documents.

Separate but highly-integrated modules combine to offer you a sophisticated distribution resource planning (DRP) system. Systematize your supply chain and account for all transport shipping and inter- branch transfers with the dynamic capabilities and advanced features of PRISM. now it’s simple to plan your shipments.

Learn MoreDo you need a tool to help your company optimize product distribution activities? You need PRISM Distribution Scheduling System to evaluate your branch warehouse inventories and sales forecasts then automatically determine how much to ship, and when, in order to keep your supply chain running smoothly. This tool helps you meet your customer’s needs while minimizing distribution cost and significantly reducing product double handling. Plan, optimize and control your distribution network like never before possible with a tool designed specifically for your industry. Optimize distribution quantities using “fair-share” or priority methods.

Maintaining a safety stock and keeping product constantly available in your sales centers can be a challenge. Let PRISM generate the plan to anticipate needs and replenish product in your sales warehouses before you run out-of-stock. By generating a bill-of-lading specifically tailored to the transport schedule and the product needs of the destination warehouse, your replenishment will be accurate and reflect what is truly needed based upon inventories and anticipated sales demand.

If you want to automate the generation of driver transport schedules, let PRISM build them for you. You specify your policies, capacities, and rules such as sales center warehouse receiving hours, loading dock limits, driver requirements, etc. Then, let the system combine this data with inventories and sales forecasts to suggest pallet requirements, build load combinations, and generate a complete transport schedule that minimizes delivery conflicts, minimize dock congestion, and minimizes driver overtime and under time. The result is improved labor and equipment utilization, and significantly less time spent planning the schedules manually. The system improves communication through advance shipping notification to the receiving branch and adds consistency and standardization to the process of transport scheduling. Best of all, the system works the way you configure it. PRISM generates transport schedules using your costs, distances, drive times, driver start times, warehouse receiving hours, holidays and other information.

Achieve the following major benefits and improvements by using PRISM Production Scheduling and Raw Materials Ordering software:

Save hours of wasted time by your scheduler/planner revising schedules; let the computer do all the work

Systematically observe and work with manufacturing capacity, space and time limitation

Cut manufacturing costs and increase material and ingredient yield

Ensures continuous product availability and keeps your product flowing in the supply chain

Generate automatic and detailed production schedules, by plant, line, day and by shift

Use your manpower, warehouse storage space and production lines to their fullest benefit

Work with real-world limitations and preferences

Double check the viability of scheduled orders automatically using the system; see system generated “red-flags” if something is wrong

Confirm on a truckload-by-truckload basis orders received versus original orders

Helps your quality control laboratory and batch mixing control room

Customers

We work with some of the largest companies in the world and provide affordable solutions to businesses large and small.

The Company

The team at Prediction Software Incorporated has deep experience providing inventory, logistics and supply chain solutions. Making software that is powerful yet easy-to-use is one of our highest goals. Our systems operate on a full spectrum of computer networks and are compatible with the latest desktop and mobile operating systems from Microsoft.

Using software technology, we can help your company better serve its customers. You can rapidly modernize your information systems and quickly improve operations by using our tools. Improve your supply chain and inventory logistics now; learn how to exploit the valuable information generated and managed by our software.

We have significant experience serving process industries especially the beverage industry, including soft drink, dairy, beer, wine, bottled water and processed foods. Our software is used by companies around the world and we proudly provide the software, training and support in various languages.

Improve your customer service now and discover how PRISM can help your organization improve its supply chain and inventory logistics. You can increase your profits just like other successful companies from around the world who currently use our software products and services.